UNTAPPING MOTOR TESTS.

Jenkins Gen3 Motor Test Systems are designed with selectable voltage control and improved safety features. Built on the principles of safety, simple operation and dependable service, our systems reduce your team’s exposure to danger, while keeping your data from all Jenkins test equipment in one place, and readily available.

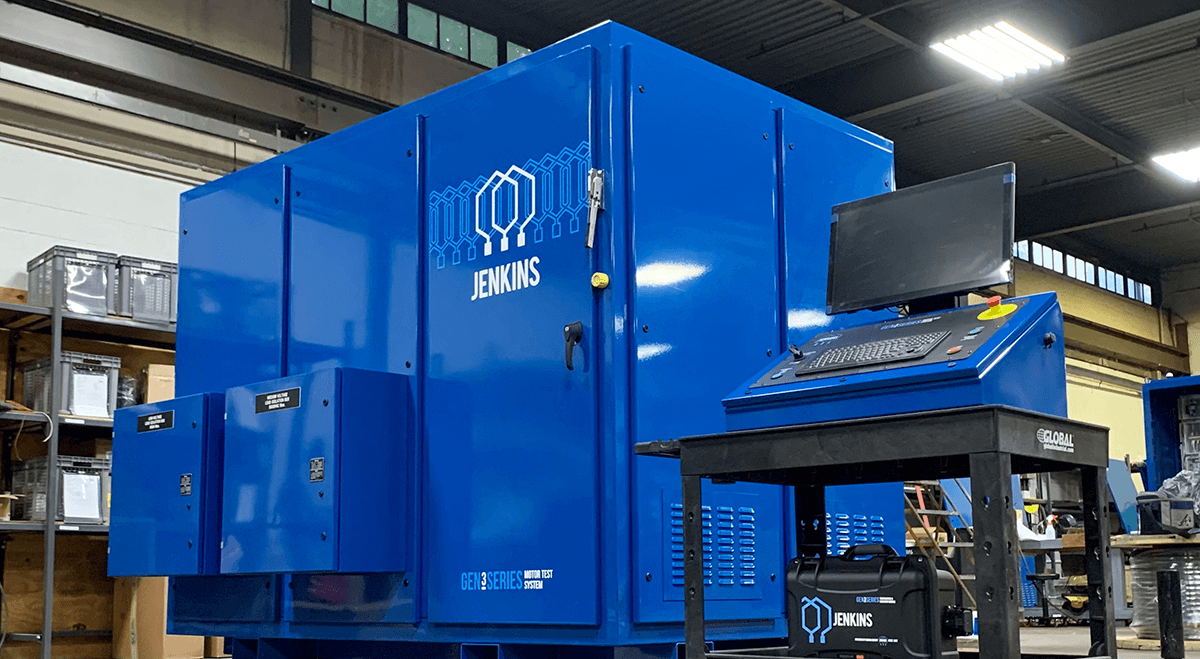

JENKINS GEN3 SERIES MOTOR TEST SYSTEM

Our Most Advanced Motor Test System

We’ve standardized our Jenkins Motor Test System on a new controls platform, which allows the set-up, voltage selection and testing of equipment to be managed entirely from the operator’s console. By removing manual tap switches, all Generation 3 systems are now fully programmable, with selectable voltages to fit your application.

All Generation 3 Motor Test Systems include an 18-month warranty, on-site technician training and commissioning, and a Jenkins-built, maintenance-free testing transformer. Remote technical support is available on networked systems.

Technical Support

Remote & On-site Support

We’ve increased our remote technical support for networked systems, providing the help you need, when you need it. When remote troubleshooting is not an option, our team of dedicated engineers and technicians are available to visit your location. Just Email Jenkins to schedule a consultation.

Data Management

Available Upgrades

Electric Motor Testing Equipment

We’re proud to be among the world’s leading testing equipment suppliers for electric motors. Our field-proven motor test systems are backed by 50 years of continuous design innovation. The goal of motor testing is to prevent unnecessary failure by evaluating the integrity of a motor in an effort to reveal hidden problems. From transducers and accessories to simple power supply upgrades and nominal meter display, Jenkins is dedicated to making sure your motors run the way they should, year after year.